Amusement Facility Operational Risk Assessments

The identification of risks will start with an evaluation of your existing safety policies, procedures and compliance with regulatory requirements. A site walk of your entire location is conducted, along with employee interviews and operational observations to gain a comprehensive understanding of your safety landscape. From this risk assessment, a roadmap for remediation can be developed while considering risk frequency, severity, and tolerance.

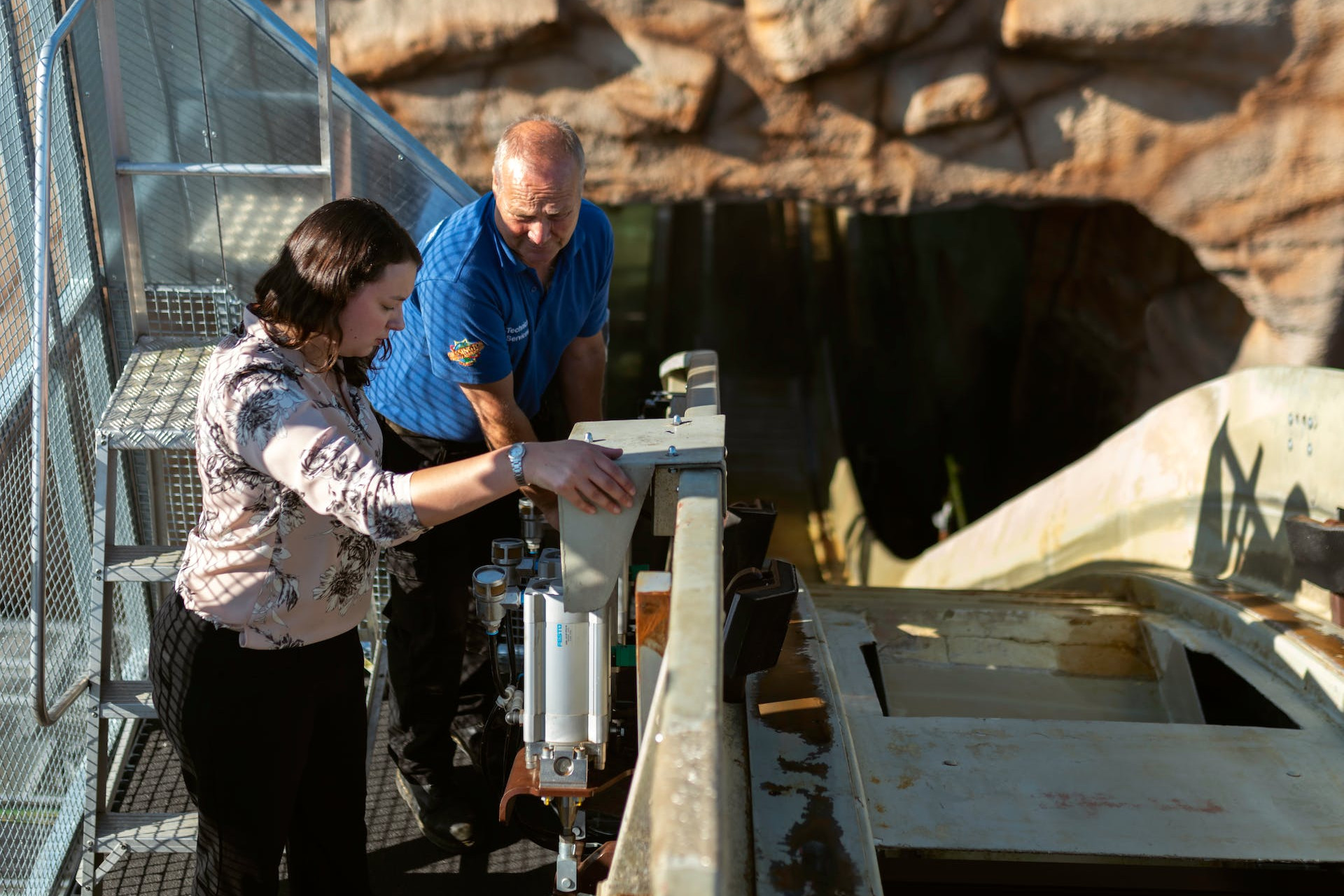

Amusement Ride Inspections

Ride and maintenance inspections by certified and experienced inspectors for an entire theme park, waterpark or FEC operation, new ride installation and audits, as well as pre-opening inspections for fairs and festivals.

SimOSHA (simulated OSHA inspections)

A simulated OSHA inspection report will provide valuable information on OSHA compliance deficiencies at your operation. With that knowledge, a remediation action plan can be developed and executed with a follow-up audit ensuring continued compliance.

Safety Program Development & Audits

Safety consultants will develop safety programs through collaboration between management teams, employees and other stakeholders by accounting for both the commonly understood risks, newly identified risks from a risk assessment, and those risks that are unique to that location. Safety Cultures are driven by training, polices, safe procedures and guidelines that promote safe and healthy work environments.

Customized Web-Based or Onsite Employee Training Programs

Safety consultants can provide on-site or virtual training on risk assessment, risk prioritization, control and remediation development, performing site evaluations and for OSHA compliance. Web-based customized educational pathways can also be designed for all employees, for groups of employees, for individual departments, or for specific job functions and can include scored testing with minimum score requirements, and certification.

Operational Safety Audits

Assessing risks and preparing a remediation plan to reduce your risk exposure is incomplete without periodic safety audits of those controls. Without performing audits, previously identified and mitigated risks can return due to changes in personnel or operational creep as controls are distorted or broken to allow for authorized changes in how operations are being performed now versus how they were performed previously, or due to a relaxed enforcement environment which can foster apathy or negligence in the maintenance of the controls. Regular periodic audits identify the need to update prior controls to changes made in operations, and controls that are not being enforced, or maintained poorly.

Incident Investigation

While we never want an incident to occur at a facility, in the unfortunate event that one does, it is imperative to perform a thorough incident investigation including witness statements, attraction or operational assessments and develop a root-cause analysis that defines what contributing factors aligned, as they often do, that created an environment that allowed the incident to occur. Once determined, an action plan to implement new controls, revise others, and create or update relevant policies and procedures can be documented and executed to prevent such an environment from developing in the future.

Policy & Procedure Development & Audits

“Almost every location I’ve performed a risk assessment on has had outdated policies, the absence of some policies, or the failure to execute their own policy as it states. All three create significant liabilities, followed by challenging litigation.”

Every location has policies and procedures, but not every location has all the ones they should have, or are required to have, or have reviewed them to confirm the reality they propose matches the reality of their execution. Processes change, and often with good reason – but the written procedures or policies are left behind.

Mismatched documentation not only impacts training of new employees when the trainer has to verbally correct against the document during training, but in litigation, this mismatch exposes the operation to embarrassing, and potentially expensive outcomes. It also invites further scrutiny with other compliance and operational questions and documentation gathering. An audit of your policies and procedures, and a gap analysis to create documentation that should exist but doesn’t, will eliminate this risk exposure.